Guddiga PCB Hard Hard Gold FR4 Wax Soo Saarka PCB Multilayer Adag

Macluumaadka aasaasiga ah

| Qaabka No. | PCB-A14 |

| Xidhmada gaadiidka | Xirmooyinka vacuum |

| Shahaado | UL,ISO9001&ISO14001,RoHS |

| Codsiga | Elektrooniga macaamiisha |

| Meesha ugu yar/khadka | 0.075mm/3mil |

| Awood-soo-saarka | 50,000 sqm/bishii |

| Koodhka HS | 853400900 |

| Asal ahaan | Lagu sameeyay Shiinaha |

Sharaxaada Alaabta

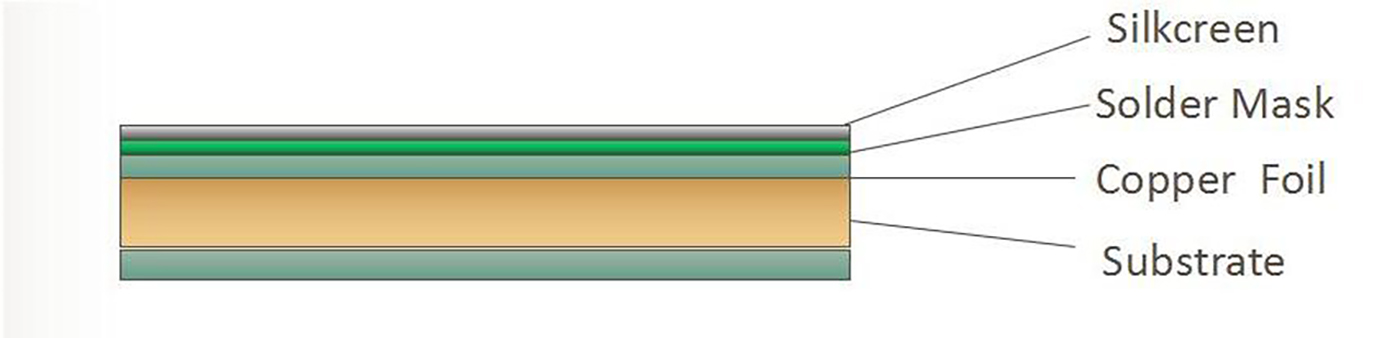

FR4 PCB Hordhac

FR macneheedu waa "holac-dejinta," FR-4 (ama FR4) waa calaamadda NEMA ee loogu talagalay walxaha laminate ee la xoojiyay muraayadda epoxy, walxo isku dhafan oo ka kooban maro fiberglass ah oo leh xiraha epoxy resin kaaso ka dhigaya mid ku habboon qaybaha elektaroonigga ah. sabuurad wareeg ah oo daabacan.

Faa'iidooyinka iyo khasaaraha FR4 PCB

Qalabka FR-4 waa mid caan ah sababtoo ah tayada badan ee cajiibka ah ee ka faa'iideysan kara looxyada wareegyada daabacan.Marka laga soo tago inay tahay mid la awoodi karo oo ay fududahay in lagu shaqeeyo, waa dahaye koronto oo leh awood koronto oo aad u sareysa.Waxaa dheer, waa mid waara, qoyaan u adkaysta, heerkulka u adkaysta oo fudud.

FR-4 waa walxo si ballaaran loo isticmaalo, caan ku ah inta badan qiimaheeda hoose iyo xasilloonida makaanikada iyo korantada.Inkasta oo maaddadani ay leedahay faa'iidooyin ballaadhan oo lagu heli karo dhumucyo iyo cabbirro kala duwan, maaha doorashada ugu fiican ee codsi kasta, gaar ahaan codsiyada soo noqnoqda sida RF iyo naqshadaha microwave.

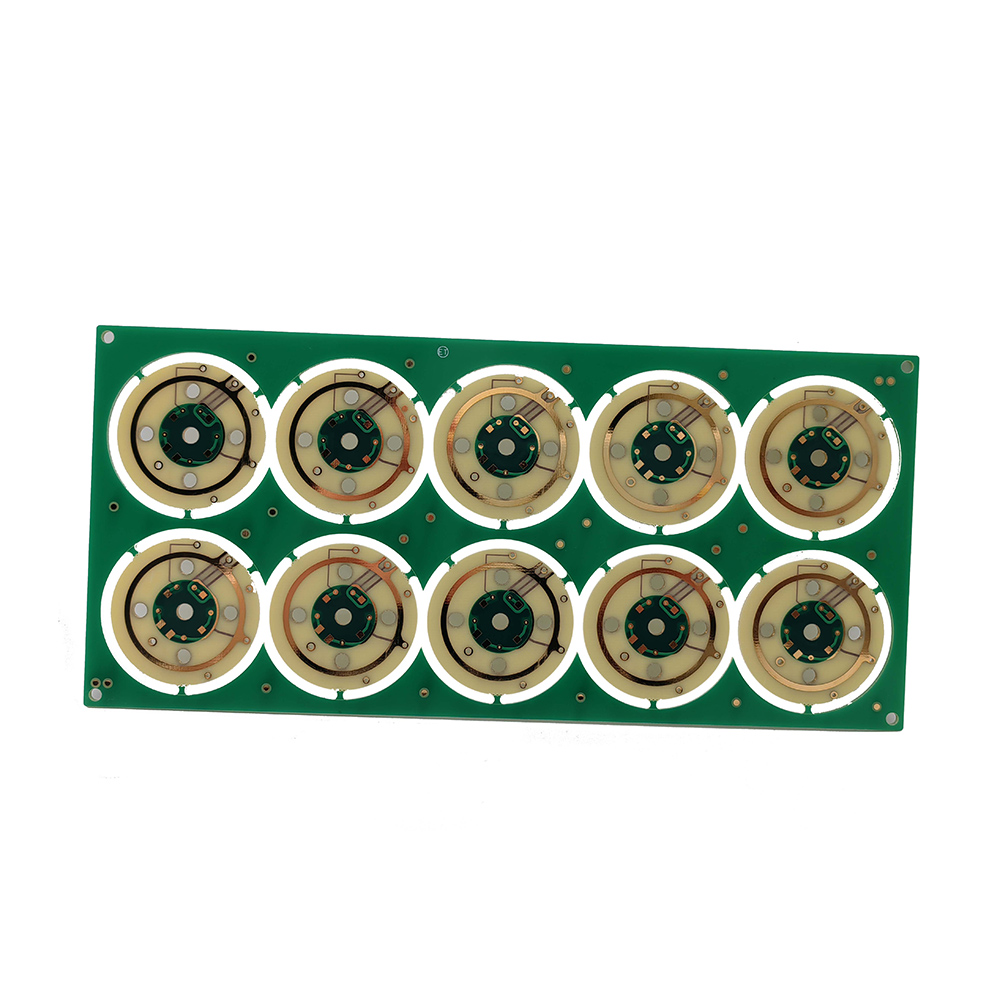

Qaab-dhismeedka PCB-yada laba-geesoodka ah

PCB-yada laba-geesoodka ah waxay u badan tahay inay yihiin nooca ugu badan ee PCB-yada.Si ka duwan PCB-yada hal lakab, oo leh lakabka korantada ee hal dhinac ee looxa, PCB-ga laba-geesoodka ah wuxuu la socdaa lakabka naxaasta ah ee labada dhinac ee looxa.Wareegyada elektarooniga ah ee hal dhinac oo ka mid ah guddiga ayaa lagu xiri karaa dhinaca kale ee looxa iyadoo la kaashanayo godad (vias) laga dhex qoday looxa.Awood u lahaanshaha isgoysyada sare ilaa hoose waxay si weyn u kordhisaa dabacsanaanta naqshadeeyaha wareegga ee naqshadeynta wareegyada waxayna isku daydaa inay si weyn u korodho cufnaanta wareegga.

Qaab dhismeedka PCB-da lakabka badan

PCB-yada Multilayer waxay sii kordhiyaan kakanaanta iyo cufnaanta naqshadaha PCB iyagoo ku daraya lakabyo dheeraad ah oo ka baxsan lakabyada sare iyo hoose ee lagu arkay looxyo laba dhinac ah.PCB-yada Multilayer waxaa lagu dhisay iyadoo la saarayo lakabyada kala duwan.Lakabyada gudaha, sida caadiga ah looxyada wareega ee laba-geesoodka ah, waa la is dulsaaray, oo leh lakabyo dahaadh ah oo u dhexeeya iyo inta u dhaxaysa naxaasta-foil-ka ee lakabyada dibadda.Godad laga dhex qoday looxa (vias) waxa ay xidhiidh la samayn doonaan lakabyada kala duwan ee looxa.

Xagee bay ka yimaadaan walxaha resin ee ABIS?

Badi iyaga oo ka socda Shengyi Technology Co., Ltd. (SYTECH), kuwaas oo ahaa soo saaraha labaad ee CCL ee ugu weyn adduunka marka loo eego mugga iibka, laga bilaabo 2013 ilaa 2017. Waxaan aasaasay xiriirka muddada dheer ee iskaashiga ilaa 2006. Qalabka resin FR4 (Model S1000-2, S1141, S1165, S1600) ayaa inta badan loo isticmaalaa samaynta loox wareegyada daabacan oo hal iyo laba-dhinac ah iyo sidoo kale loox-lakabyo badan.Halkan waxaa ku qoran faahfaahinta tixraacaada.

Loogu talagalay FR-4: Sheng Yi, King Board, Nan Ya, Polycard, ITEQ, ISOLA

Loogu talagalay CEM-1 & CEM 3: Sheng Yi, King Board

Soo noqnoqoshada Sare: Sheng Yi

Daawada UV: Tamura, Chang Xing (* Midabka la heli karo: Cagaaran) Alxanka dhinaca

Sawirka dareeraha ah: Tao Yang, iska caabin (filimka qoyan)

Chuan Yu (* Midabada la heli karo: Cadaan, Jaalle la qiyaasi karo Alxanka, Purple, Cas, Buluug, Cagaaran, Madow)

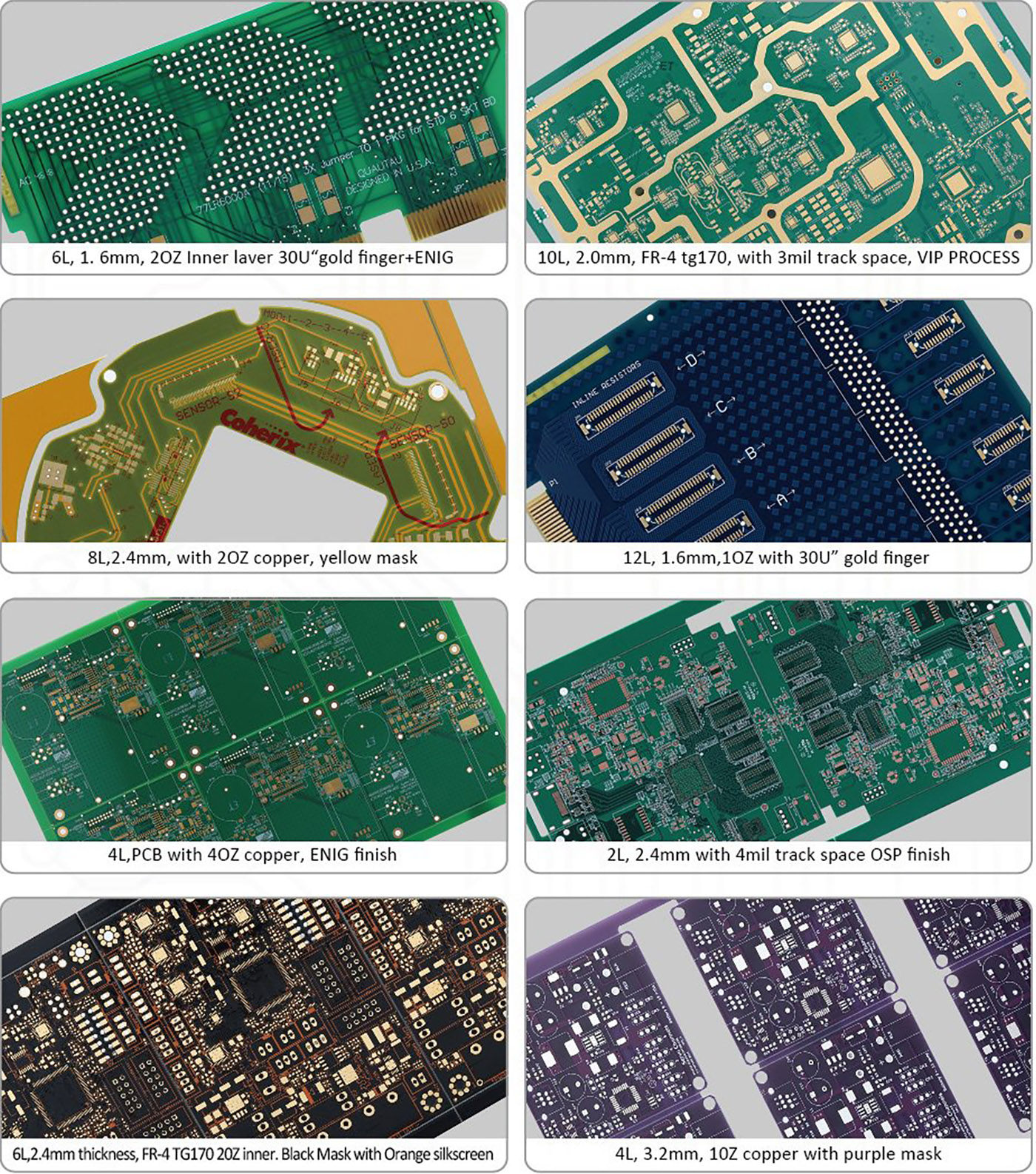

Farsamo & Karti

ABIS waxay khibrad u leedahay samaynta qalab gaar ah oo loogu talagalay PCB adag, sida: CEM-1/CEM-3, PI, High Tg, Rogers, PTEF, Alu/Cu Base, iwm. Hoos waxaa ah dulmar kooban FYI.

| Shayga | Awood-soo-saarka |

| Tirada lakabka | 1-20 lakab |

| Qalab | FR-4, CEM-1/CEM-3, PI, High Tg, Rogers, PTEF, Alu/Cu Base, iwm |

| Dhumucda looxa | 0.10mm-8.00mm |

| Cabirka ugu badan | 600mmX1200mm |

| Dulqaadka dulucda guddiga | +0.10mm |

| Dulqaadka Dhumucda (t≥0.8mm) | ± 8% |

| Dulqaadashada Dhumucda (t<0.8mm) | ± 10% |

| Dhumucda lakabka dahaarka | 0.075mm--5.00mm |

| Khadka ugu yar | 0.075mm |

| Meesha ugu yar | 0.075mm |

| Lakabka ka baxay Dhumucda Copper | 18um--350um |

| Lakabka Gudaha Dhumucda Naxaasta | 17um--175um |

| Daloolka Qodista ( Makaanikada) | 0.15mm--6.35mm |

| Dhammaystirka Godka ( Makaanikada) | 0.10mm-6.30mm |

| Dulqaadka Dhexroorka (Mashiinka) | 0.05mm |

| Diiwaangelinta | 0.075mm |

| Saamiga dhinaca | 16:1 |

| Nooca Maaskarada Alxan | LPI |

| SMT Mini.Balacda Maaskarada Alxan | 0.075mm |

| MiniNadiifinta Maaskarada Alxan | 0.05mm |

| Dhererka godka | 0.25mm--0.60mm |

| Dulqaadashada xakamaynta caqabada | ± 10% |

| Dhammaadka/daawaynta dusha sare | HASL, ENIG, Chem, Tin, Flash Gold, OSP, Far dahab ah |

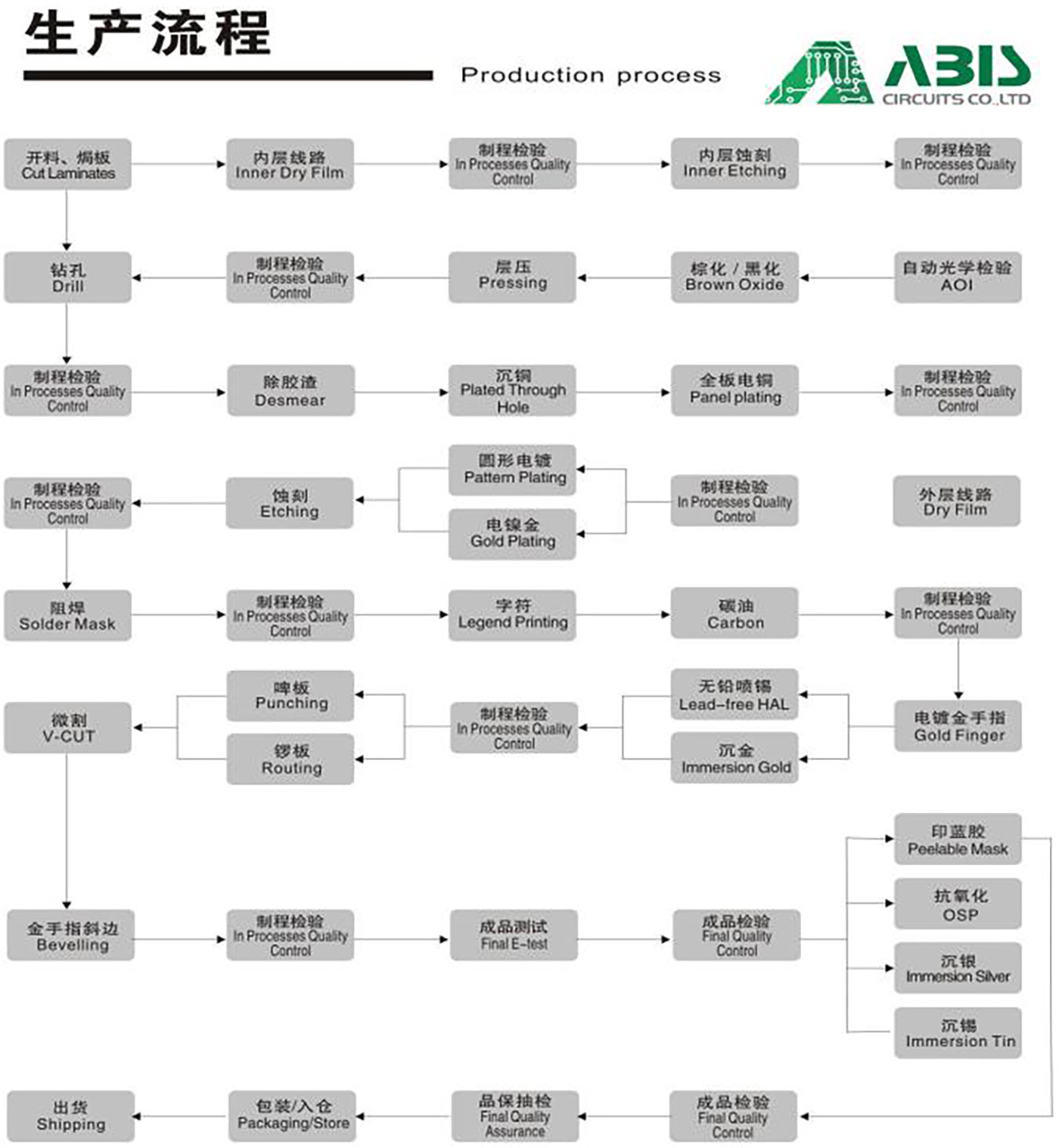

Habka Waxsoosaarka PCB

Nidaamku wuxuu ka bilaabmaa qaabaynta Qaabka PCB-ga iyadoo la adeegsanayo barnaamij kasta oo PCB nashqadeynaya / Qalabka CAD (Proteus, Eagle, Ama CAD).

Dhammaan tallaabooyinka soo haray waa Habka Wax-soo-saarka ee Guddiga Wareegga Daabacan ee Adag waxay la mid yihiin PCB-ga Hal dhinac ah ama PCB-ga laba-geesoodka ah ama PCB-da lakabka badan.

Wakhtiga Hogaaminta Q/T

| Qaybta | Waqtiga Hogaaminta ugu Dhakhsaha badan | Waqtiga Hogaaminta Caadiga ah |

| Laba-dhinac | 24 saac | 120 saac |

| 4 Lakabyo | 48 saac | 172 saac |

| 6 Lakabyo | 72 saac | 192 saac |

| 8 Lakabyo | 96 saac | 212 saac |

| 10 Lakab | 120 saac | 268 saac |

| 12 lakab | 120 saac | 280 saac |

| 14 Lakab | 144 saac | 292 saac |

| 16-20 lakab | Waxay kuxirantahay shuruudaha gaarka ah | |

| In ka badan 20 lakab | Waxay kuxirantahay shuruudaha gaarka ah | |

Dhaqdhaqaaqa ABIS ee lagu xakameynayo FR4 PCBS

Diyaarinta godka

Ka-saarista qashinka si taxadar leh & hagaajinta cabbirada mishiinka: ka hor inta aanad ku dhejin naxaas, ABIS waxay si taxadar leh u fiirisaa dhammaan godadka FR4 PCB ee lagu daweeyey si looga saaro qashinka, cilladaha dusha sare, iyo smear epoxy, godadka nadiifka ah waxay hubiyaan in dahaadhku si guul leh ugu dheggan yahay derbiyada daloolka. .sidoo kale, horraantii habka, cabbirada mishiinka daloolka ayaa si sax ah loo hagaajiyaa.

Diyaarinta Dusha sare

Si taxaddar leh uga-hortagga: Shaqaalaheenna tignoolajiyada khibradda leh waxay ogaan doonaan waqti ka hor in habka kaliya ee looga fogaado natiijada xun ay tahay in la saadaaliyo baahida loo qabo maaraynta gaarka ah iyo in la qaado tillaabooyinka ku habboon si loo hubiyo in habka loo sameeyay si taxadar leh oo sax ah.

Heerarka Balaadhinta kulaylka

Caadada u ah wax ka qabashada walxaha kala duwan, ABIS waxay awood u yeelan doontaa inay falanqeyso isku darka si loo hubiyo inay ku habboon tahay.ka dib ilaalinta isku halaynta muddada dheer ee CTE (isku-dhafka balaadhinta kulaylka), iyada oo CTE-da hoose, ay yar tahay suurtogalnimada in godadka lagu dhejiyo ay ku guuldareystaan dabacsanaanta soo noqnoqda ee naxaasta taasoo sameysa isku xirnaanta lakabka gudaha.

Cabbiraadda

Xakamaynta ABIS wareegga wareegga waxaa lagu kordhiyey boqolleyda la og yahay iyadoo la filayo khasaarahan si ay lakabyadu ugu soo noqdaan cabbirkooda sidii loo qaabeeyey ka dib marka wareegga lamination la dhammeeyo.sidoo kale, iyadoo la adeegsanayo talooyinka cabbiraadda aasaasiga ah ee saaraha laminateerka oo ay weheliso xogta habraaca tirakoobka ee guriga dhexdiisa, si loo garaaco qodobbada cabbirka ee socon doona muddo ka dib gudaha deegaanka wax soo saarka ee gaarka ah.

Makiinada

Marka la gaaro wakhtiga lagu dhisayo PCB-gaaga, ABIS iska hubi inaad dooratay inaad haysato qalabka saxda ah iyo waayo-aragnimada aad si sax ah ugu soo saari karto isku dayga ugu horreeya.

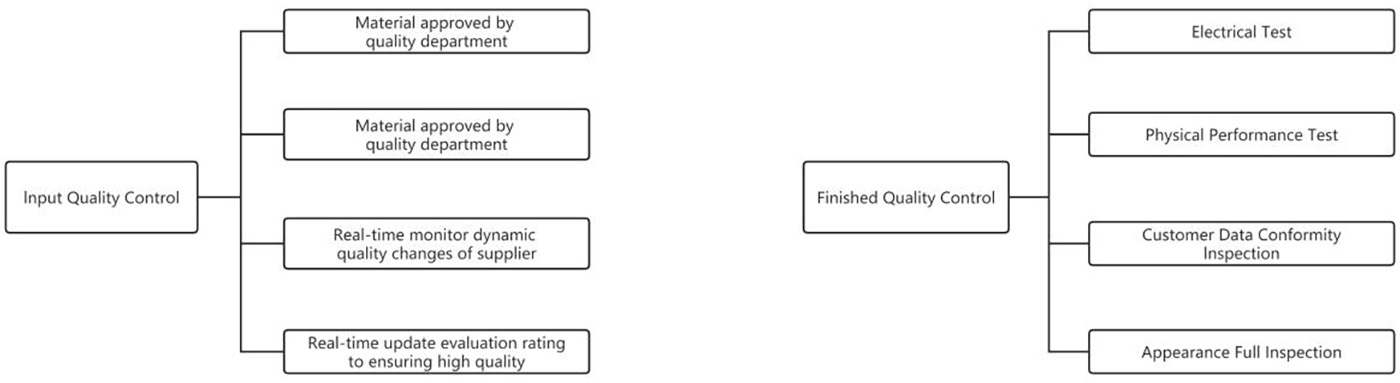

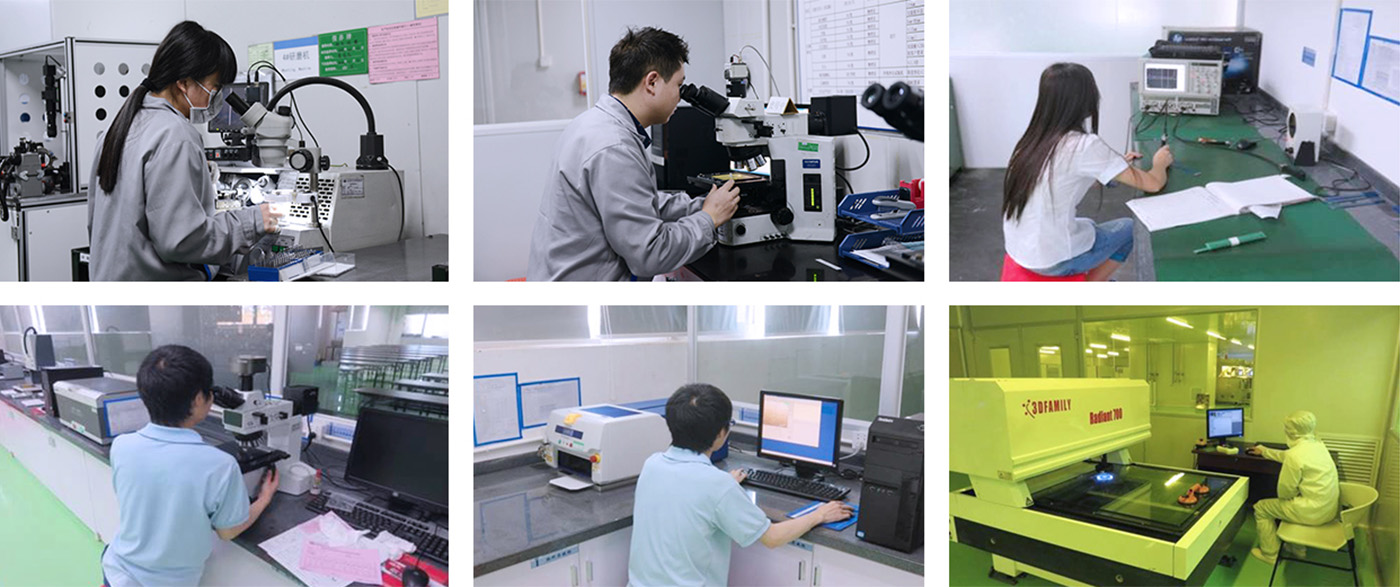

Xakamaynta tayada

BIS waxay xallisaa aluminium PCB dhibaatada?

Alaabta ceeriin si adag ayaa loo xakameeyaa:Heerka gudbinta ee alaabta soo socota ayaa ka sarreysa 99.9%.Tirada diidmada tirada badan waxay ka hooseysaa 0.01%.

Etching Copper waa la xakameeyey:xaashida naxaasta ah ee loo isticmaalo PCB-yada Aluminiumku marka la barbardhigo waa ka dhumuc weyn yihiin.Haddii xaashida naxaasta ah ay ka badan tahay 3oz si kastaba ha ahaatee, xoqintu waxay u baahan tahay magdhow ballac ah.Qalabka saxda ah ee saxda ah ee laga keeno Jarmalka, min ballac / meel bannaan oo aan xakameyn karno waxay gaartaa 0.01mm.Magdhawga ballaca raadraaca ayaa si sax ah loo nakhshadeeyay si looga fogaado in ballaca raadku aanu dulqaad lahayn ka dib xoqidda.

Daabacaadda Maaskarada Alxan Tayada Sare leh:Sida aan wada ognahay, waxaa dhib ku ah daabacaadda maaskaro alxanka PCB oo ay ugu wacan tahay dhumucda naxaasta.Tani waa sababta oo ah haddii naxaasta raadku aad u dhumuc weyn yahay, markaa sawirka la xardhay wuxuu yeelan doonaa farqi weyn oo u dhexeeya dusha sare ee raadadka iyo guddiga saldhigga iyo daabacaadda maaskarada alxanka ayaa adkaan doonta.Waxaan ku adkeysaneynaa heerarka ugu sarreeya ee saliidda maaskarada ee habka oo dhan, laga bilaabo mid ilaa laba-jeer daabacaadda maaskaro.

Farsamaynta Farsamada:Si looga fogaado hoos u dhigista awoodda korantada ee ay keento habka wax soo saarka farsamada, waxay ku lug leedahay qodista farsamada, naqshadaynta iyo v-dhibcaha iwm. Sidaa darteed, wax-soo-saarka mugga hoose ee alaabta, waxaan mudnaanta siineynaa isticmaalka mishiinka korontada iyo gooyaha xirfadlaha ah.Sidoo kale, waxaan fiiro gaar ah u siineynaa hagaajinta cabbirada qodista iyo ka hortagga burka inuu soo saaro.

Shahaado

FAQ

Lagu hubiyay 12 saacadood gudahoodMarka la hubiyo su'aasha Engineerka iyo faylka shaqada, waxaan bilaabi doonaa wax soo saarka.

ISO9001, ISO14001, UL USA & USA Canada, IFA16949, SGS, RoHS warbixinta.

Hababkayada Hubinta Tayada sida hoos ku qoran:

a), Kormeerka muuqaalka

b), Baadhitaanka duulista, qalabka lagu rakibo

c) Xakamaynta dhibka

d) Ogaanshaha kartida alxanka

e).

f), AOI (Baaritaanka Indhaha oo Toomaatig ah)

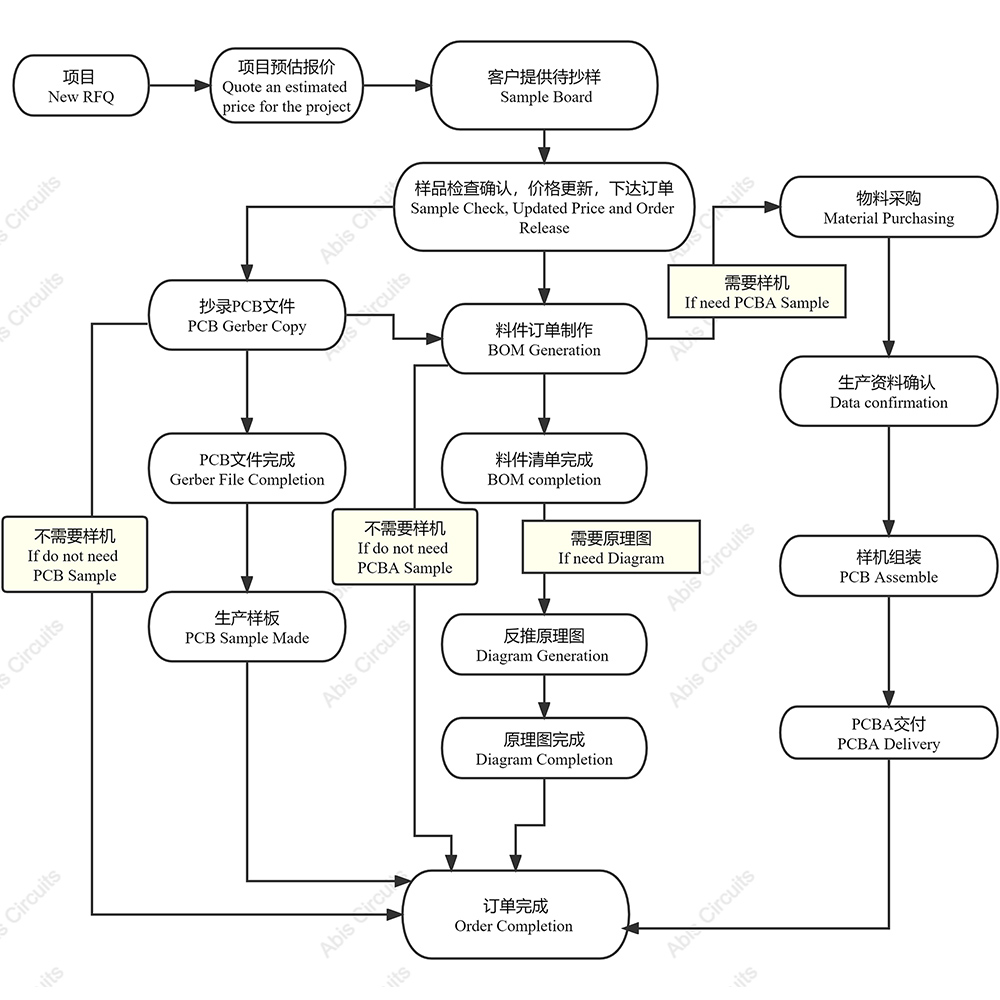

Maya, ma awoodnoaqbalfiles sawir, haddii aadan haysanGerberfile, ma noo soo diri kartaa muunad si aad u koobiyeyso.

PCB&PCBA Habka koobiga:

Heerka gaarsiinta waqtiga ayaa ka badan 95%

a), 24 saacadood oo degdeg ah u leexo labada dhinac ee PCB

b), 48 saacadood 4-8 lakab oo ah nooca PCB

c), 1 saac oo xigasho

d), 2 saacadood oo loogu talagalay su'aalaha injineernimada / jawaab celinta cabashada

e), 7-24 saacadood ee taageerada farsamada/dalabka adeegga / hawlgallada wax soo saarka

ABIS ma laha shuruudaha MOQ ee PCB ama PCBA midkood.

Waxaan ka qayb galnaa bandhigyo sanad walba, kii ugu dambeeyay ayaa ahExpo Electronica&ElectronTechExpo ee Russia taariikhdu markay ahayd Abriil 2023. Filo booqashadaada.

ABlS waxay qabataa 100% muuqaal iyo kormeer AOl iyo sidoo kale samaynta tijaabinta korantada, tijaabinta korantada sare, tijaabada xakamaynta xakamaynta, qayb yar oo ka mid ah, tijaabinta shoogga kulaylka, tijaabinta alxanka, tijaabinta isku halaynta, tijaabinta caabbinta dahaarka, tijaabada nadaafadda ionic iyo tijaabinta PCBA.

a), Xigasho 1 saac ah

b), 2 saacadood oo jawaab celin cabasho ah

c), 7*24 saac taageero farsamo

d), 7*24 adeeg dalbashada

e), 7*24 saac gaarsiinta

f),7*24 wax soo saar

| Awoodda wax soo saarka ee alaabta iibka kulul | |

| Aqoon-is-weydaarsiga PCB-ga ee laba-geesoodka ah | Aluminium PCB Workshop |

| Karti Farsamo | Karti Farsamo |

| Qalabka ceeriin: CEM-1, CEM-3, FR-4 (High TG), Rogers, TELFON | Qalabka ceeriin: Saldhig aluminium, saldhigga naxaasta |

| Lakab: 1 lakab ilaa 20 lakab | Lakabka: 1 lakab iyo 2 lakab |

| Balaadhka khadka ugu yar: 3mil/3mil(0.075mm/0.075mm) | Balaadhka khadka ugu yar: 4mil/4mil(0.1mm/0.1mm) |

| Daloolkii ugu yaraa: 0.1mm (dalool dalool) | Min.Cabbirka daloolka: 12mil (0.3mm) |

| Max.Cabbirka looxa: 1200mm* 600mm | Cabbirka ugu sarreeya: 1200mm* 560mm(47in* 22in) |

| Dhumucdiisuna waxay dhammaatay: 0.2mm- 6.0mm | Dhumucdiisuna waxay dhammaatay: 0.3 ~ 5mm |

| Dhumucdiisuna waxay tahay xaashida naxaasta ah: 18um ~ 280um (0.5oz ~ 8oz) | Dhumucdiisuna waxay tahay 35um ~ 210um (1oz ~ 6oz) |

| Dulqaadka NPTH: +/- 0.075mm, Dulqaadka PTH: +/- 0.05mm | Dulqaadka booska daloolka: +/- 0.05mm |

| Dulqaadka dulucda: +/- 0.13mm | Dulqaadka dulsaarka dariiqa: +/ 0.15mm;Dulqaadka dulucda feerka:+/ 0.1mm |

| Dusha sare ayaa dhammaatay: HASL-ka-free-lead, Dahab immersion(ENIG), qalin immersion, OSP, dahaadh dahab ah, far dahab ah, Kaarboon INK. | Dusha sare ayaa dhammaatay: HASL bilaash ah, dahab immersion (ENIG), qalin immersion, OSP iwm |

| Dulqaadka xakamaynta xakamaynta: +/- 10% | U dulqaadashada dhumucda hadhaa: +/- 0.1mm |

| Awood wax soo saar: 50,000 sqm / bishii | Awoodda Wax-soo-saarka MC PCB: 10,000 sqm/bishii |